Image copyright GETTY IMAGES

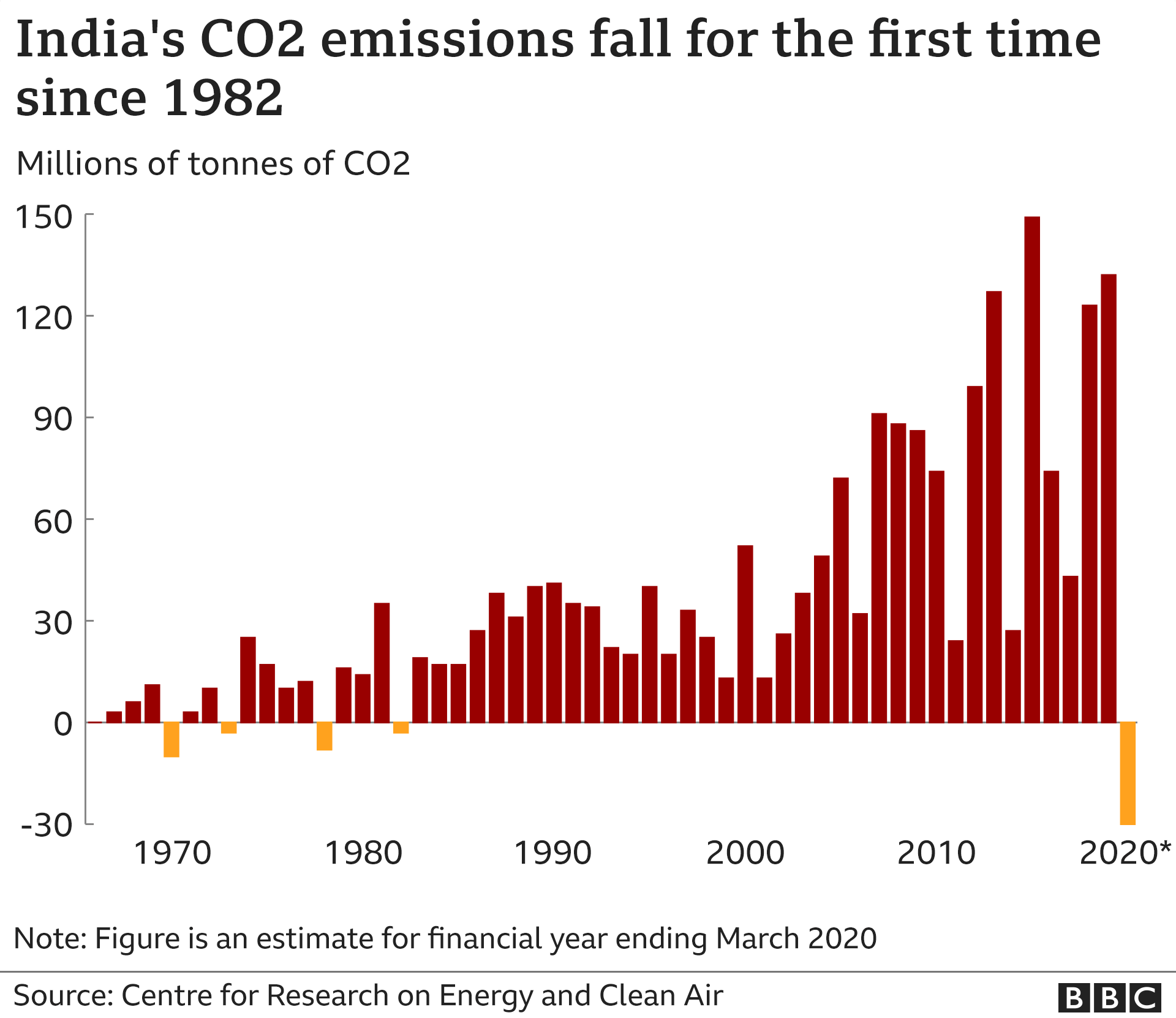

Image copyright GETTY IMAGESIndia’s CO2 emissions have fallen for the first time in four decades – and not just as a result of the country’s coronavirus lockdown.

Falling electricity use and competition from renewables had weakened the demand for fossil fuels even before the coronavirus hit, according to analysis by the environmental website, Carbon Brief. However, it was the sudden nationwide lockdown in March that finally tipped the country’s 37-year emissions growth trend into reverse.

The study finds that Indian carbon dioxide emissions fell 15% in March, and are likely to have fallen by 30% in April.

Virtually all of the drop-off in power demand has been borne by coal-fired generators, which explains why the emissions reductions have been so dramatic.

Coal-fired power generation was down 15% in March and 31% in the first three weeks of April, according to daily data from the Indian national grid.

But even before India’s sudden coronavirus lockdown, the demand for coal was weakening.

The study finds that in the fiscal year ending March 2020, coal deliveries were down by around 2%, a small but significant reduction when set against the trend – an increase in thermal power generation of 7.5% a year set over the previous decade.

Indian oil consumption shows a similar reduction in demand growth.

Image copyright GETTY IMAGES

Image copyright GETTY IMAGESIt has been slowing since early 2019.

And, once again, the trend has been compounded by the impact of the Covid-19 lockdown measures on the transport industry.

- India’s double first in climate battle

- How India’s ‘smart villages’ are centralising solar power

- Why power theft in India is a complex problem

Oil consumption was down 18% year-on-year in March 2020.

Meanwhile, the supply of energy from renewables has increased over the year and has held up since the pandemic struck.

This resilience the renewables energy sector shows in the face of the sudden reduction in demand caused by coronavirus is not confined to India.

According to figures published by the International Energy Agency (IEA) at the end of April, the world’s use of coal was down 8% in the first quarter of the year.

By contrast, wind and solar power saw a slight uptick in demand internationally.

A key reason that coal has taken the brunt of the fall in electricity demand is that it cost more to run on a day-to-day basis.

Once you have installed a solar panel or a wind turbine, operating costs are very low and, therefore, tend to get priority on electricity grids.

Image copyright GETTY IMAGES

Image copyright GETTY IMAGESThermal power stations – those powered by coal, gas or oil – by contrast, require you to buy fuel in order to generate power.

But analysts warn that the decline in fossil fuel use may not last.

They say when the pandemic subsides, there is a risk that emissions will soar again as countries attempt to kick-start their economies.

The US has already started to relax environmental regulations and the fear is other nations could follow suit.

However, the analysis from Carbon Brief suggests there are reasons to think India could buck this trend.

The coronavirus crisis has brought the long-brewing financial troubles in the Indian coal sector to a head, and the Indian government is finalising a relief package which could top 900bn rupees ($12bn; £9.6bn).

But, at the same time, the government is talking about supporting renewable energy as part of the recovery.

Image copyright GETTY IMAGES

Image copyright GETTY IMAGESRenewables have the economic edge in India, offering far cheaper electricity than coal.

The report claims that new solar capacity can cost as little 2.55 rupees per kilowatt hour, while the average cost for electricity generated from coal is 3.38 rupees per hour.

Investing in renewables is also consistent with the country’s National Clean Air Programme, launched in 2019.

Environmentalists hope the clean air and clear skies Indians have enjoyed since lockdown will increase public pressure on the government to clean up the power sector and improve air quality.

Source: The BBC

Coronavirus: Chinese workers in Vietnam cry foul after being fired by Taiwanese firm making shoes for Nike, Adidas

A group of 150 Chinese workers believe the world’s largest maker of trainers used the coronavirus as an excuse to fire them, having helped Taiwanese firm Pou Chen successfully expand its production into Vietnam for more than a decade.

Pou Chen, which makes footwear for the likes of Nike and Adidas, informed the group in late April that they would no longer be needed as they were unable to return to

from their hometowns in China due to the coronavirus lockdowns.

“We 150 employees were the first batch of Chinese employees to be laid off this year. We are all pessimistic and expect more will be cut,” added Zhang.

In its email on April 27, Pou Chen said it was forced to terminate the contracts of the Chinese employees across five of its factories due to an unprecedented decline in orders and financial losses.

The Chinese employees, many of whom have been working for the shoemaker for decades, said the compensation offered was unfair and below the levels required by labour law in both Vietnam and China.

“[The dismissals were] in accordance with the relevant labour laws of the country of employment … and employee labour contracts,” added the statement from Pou Chen, which employs around 350,000 people worldwide.

Company data showed Pou Chen’s first quarter revenues tumbled 22.4 per cent year-on-year to NT$59.46 billion (US$1.99 billion), the weakest in six years.

With the likes of Nike and Adidas closing retail stores around the world to comply with social distancing requirements, analysts also said orders plummeted 50 per cent in the second quarter, although the company declined to comment on the media reports.

Andy Zeng, who had worked for the firm since 1995, said the group were “very upset” when they received the news last month as the impact of the coronavirus pandemic began to reverberate around the world, disrupting global value chains.

“Most of us joined Pou Chen in the 1990s when we were in our late teens or early 20s, when the Taiwan-invested company started investing and setting up factories in mainland China. Now more than two decades have passed,” he said.

Zeng was among the first generation of skilled workers in China as Pou Chen developed rapidly, enjoying the benefits of cheap labour, although the workers themselves were rewarded with regular pay rises.

The company needed a group of skilled Chinese workers to go to its new factories in Vietnam. I said yes because I thought it was a good opportunity to see the outside world – Andy Zeng

What our Chinese employees have done in Vietnam for more than a decade can be said to be very simple but very difficult – Dave Zhang

Posted in 50 per cent, accordance, Adidas, adjustment of manpower, around the world, automation level, below the levels, Bloomberg, boomed, bottlenecks, Chaos, cheaper, China, China’s economy, Chinese employees, Chinese workers, closing, comment, Company, compensation, comply, contributed, cooperated, coronavirus, coronavirus lockdowns, Covid-19 response, cry foul, cultural shock, deaths, decade, decline, declined, dismissals, disputes, Dong Nai, Dongguan, employee labour contracts,, expand, expendable, factories, families, financial losses, fired, footwear, furloughs, higher, hometowns, impact, Indonesia, Labour law, lack of orders, land, Mainland China, making, management experience, management style, media reports, Nike, opportunity, orders, pay cuts, pessimistic, plans, plummeted, Pou Chen, production, production line, relocation process, requirements, retail stores, returns, Reuters, Rush hour, second quarter, set up, shoe manufacturing, shoes, skilled, Social distancing, south china morning post, strain under, streets, strike, Taipei Times, Taiwan, Taiwan-invested, Taiwanese firm, Uncategorized, unfair, unprecedented, Vietnam, Vietnamese, Virus, workers, world’s largest maker of trainers | Leave a Comment »