- Developer says 15-metre span is an example of the many possibilities of the new technology

- Sturdy design means bridge is strong enough to support four adults per square metre, engineer says

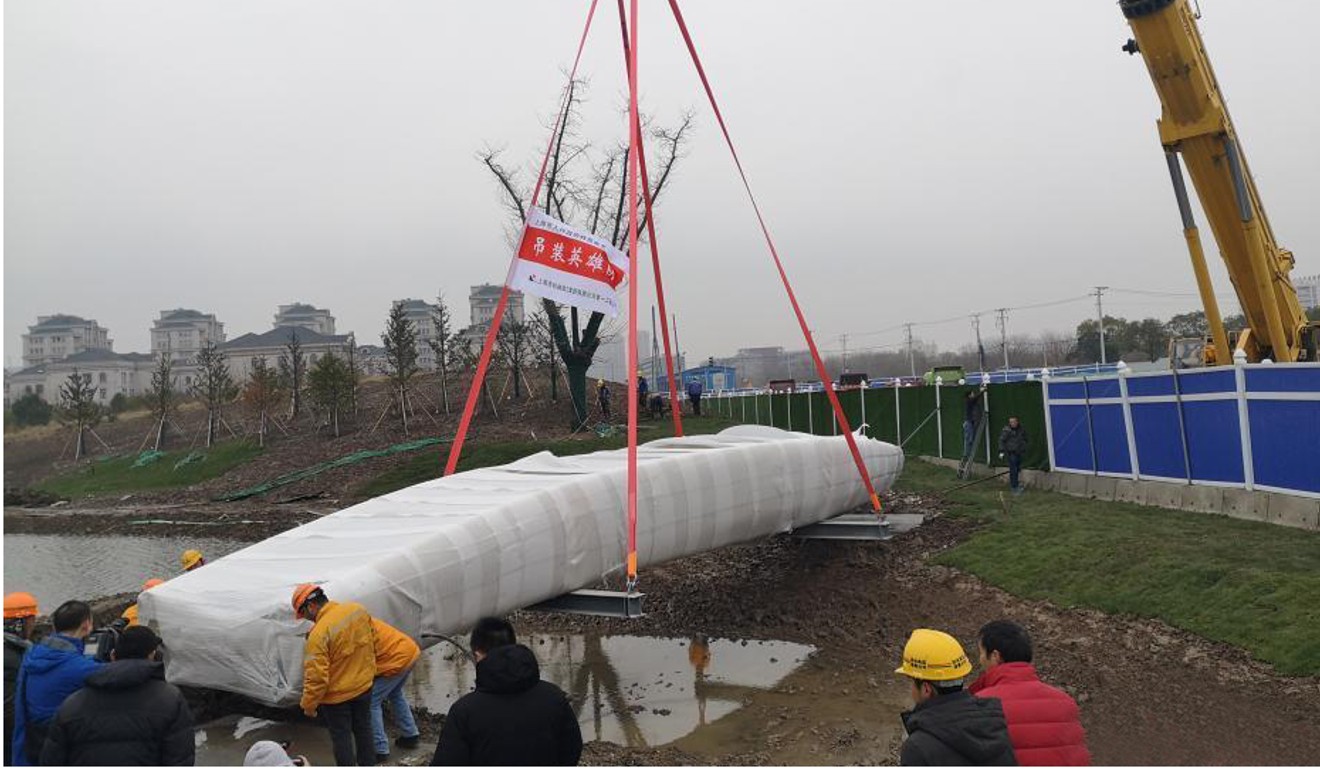

The span, which opened for business on Friday, was created by Shanghai Machinery Construction Group using materials made by Polymaker, the state-run China News Service reported.

“It’s both an everyday, practical application and an interactive one that involves people touching and even relying upon … a 3D printed thing,” Polymaker said on its website.

“Many people have never touched a 3D printed object and they still think of it as part fantasy and part future tech, so projects like this do a lot of good in terms of exposing the public to the reality and the possibilities of 3D printing,” it said.

The footbridge, which engineers said should last about 30 years, was installed over a narrow creek at the Taopu Smart City complex in Shanghai’s Putuo district, the news report said.

Polymaker said the machine used to print the bridge, which is 3.8 metres wide, 1.2 metres deep and about 5,800kg (12,800lbs) in weight, cost US$2.8 million.

The span was made as a single piece from a combination of glass fibre and a printable plastic filament known as acrylonitrile styrene acrylate, it said.

A separate report by Xinming Evening News quoted an engineer as saying the bridge was capable of bearing a load of 250kg per square metre, or about the weight of four adults.

Before starting the printing process, the build team spent 18 months in research and planning, it said.

While the Shanghai bridge is the first of its kind in China, it is not a world first in terms of 3D printing.

That honour goes to a 12-metre walkway installed at a park in Madrid in 2017, while a 3D-printed steel bridge was unveiled in the Netherlands in October.

COMMENTS: